In rapeseed (canola) oil production, consistent control of temperature, time, and pressure—backed by reliable equipment integration—determines whether a plant delivers high yield and stable quality or struggles with losses and off-spec batches. Plants that implement disciplined parameter windows typically capture 0.3–0.8% extra oil yield, reduce steam consumption by 8–15%, and cut unplanned downtime by 10–20%. The following technical guide maps each step—from seed preparation and mechanical pressing to physical/chemical refining—pinpointing set-points, cause–effect logic, and optimization levers proven in industrial operations.

Target foreign matter ≤0.5% after cleaning using scalpers, aspirators, and destoners. Install ≥8000 Gauss magnets ahead of presses and pumps to protect screws, pumps, and heat exchangers.

Adjust seed moisture to 6.5–8.5% for mechanical stability and efficient cell rupture. Typical conditioner setpoints: 60–75°C outlet temperature with 15–25 minutes residence. For hot pressing, a short high-temperature stage (up to 90–105°C) improves oil release but must be controlled to limit phospholipid hydration and color precursors.

Optional dehulling reduces fiber load and press wear. Where implemented, aim for hull removal 10–20% by mass, keeping protein and oil losses minimal through aspiration balance and sieve tuning.

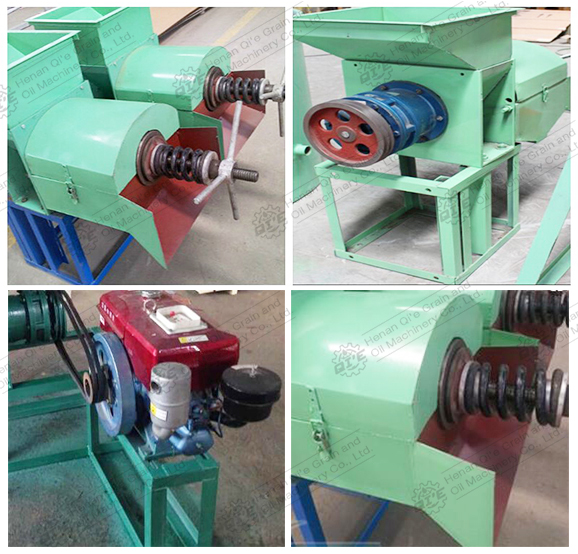

For edible-grade cold brands, maintain press inlet 60–70°C (or lower for “cold press” claims) and 18–24 rpm screw speed depending on shaft geometry. Typical cake residual oil: 12–18%, oil yield 80–86% of seed oil content. Expect energy 35–55 kWh/t seed for pressing and ≤0.5% fines in crude oil after decanting/filters.

Pre-press to 18–22% residual oil, then extract with food-grade hexane in a continuous extractor. Typical solvent consumption 2.5–3.5 kg/t seed; desolventize-toaster (DT) operates at 105–110°C with 15–25 minutes retention. Final meal hexane <300 ppm; residual oil in extracted meal 0.8–1.5%. Integrated heat recovery between miscella and meal saves 8–12% steam.

Crude oil clarification: keep settling/centrifuge inlet 60–70°C, and dose citric or phosphoric acid (10–50 ppm) to condition trace metals before refining.

Choose the route based on crude FFA and phospholipid loading. For FFA ≤1.5–2.0% and low non-hydratable gums, physical refining (acid degum → bleaching → deodorization for FFA removal) preserves more neutral oil and tocopherols. For FFA ≥2–4% or challenging gums, chemical refining (caustic neutralization) ensures predictable soapstock separation but incurs higher neutral oil losses if overdosed.

Typical settings: 70–80°C, 0.1–0.2% phosphoric acid (85%), 20–30 minutes residence with high-shear mixing then gentle hold. Hydrate with 1–3% water depending on gum content. Centrifuge to remove hydrated gums. Target P <10 ppm, metals <0.1 ppm after washing to protect bleaching and reduce 3-MCPD/GE risk downstream.

Use caustic at 12–16 °Bé with 1.1–1.3× stoichiometric based on titrated FFA. Operate at 55–65°C; separate soapstock via centrifuge. Wash 1–2 times to reduce soap to <50 ppm before bleaching. Proper dosing and mixing reduce neutral oil loss to 0.3–0.5% per 1% FFA.

Dose activated clay 0.5–1.5% (plus 0.05–0.1% activated carbon if PAHs are of concern). Operate at 90–110°C, vacuum >90 kPa absolute reduction (≤50 mbar), 20–30 minutes. Targets: PV <2 meq/kg, phosphorus <5 ppm, and stable Lovibond color (e.g., Y ≤25, R ≤2.5, 5.25” cell). Over-dosing clay increases oil retention and filter drop; tune dosage with on-line color and PV data.

Operate at 190–220°C under deep vacuum 2–6 mbar with 1–3% w/w sparge steam for 2–4 hours residence depending on column design. Targets: FFA <0.05%, POV <1 meq/kg, low anisidine value, and neutral flavor. Use structured packing, multiple trays, and heat integration (economizer + heat recovery) to minimize thermal load. To mitigate 3-MCPD esters and glycidyl esters, keep chloride precursors low (good degumming), avoid excessive acidity at high temperatures, and control deodorizer top temperature (stay conservative within spec).

For cold stability in temperate markets, chill to 0–5°C for 8–12 hours and filter through precoated filters. Aim for cloud point ≤0°C without stripping tocopherols; a short, gentle cycle is sufficient for rapeseed vs. high-wax seed oils.

| Step | Key Parameters | Primary Targets |

|---|---|---|

| Conditioning | 60–75°C; 15–25 min; moisture 6.5–8.5% | Stable press feed; minimal fines |

| Pressing | Inlet 60–105°C; screw 18–24 rpm | Cake oil 12–18% (full-press) |

| Degumming | 70–80°C; 0.1–0.2% H3PO4; 20–30 min | P <10 ppm; metals <0.1 ppm |

| Neutralization | 12–16 °Bé NaOH; 55–65°C | Soap <50 ppm post-wash |

| Bleaching | 0.5–1.5% clay; 90–110°C; ≤50 mbar | PV <2; stable Lovibond |

| Deodorization | 190–220°C; 2–6 mbar; 1–3% steam | FFA <0.05%; POV <1 |

Plants that monitor what matters can correct deviations before product is at risk. Recommended controls include: on-line NIR moisture at conditioner discharge; load cells on press choke; torque and temperature monitoring along press barrels; inline phosphorus (or rapid test) after degumming; peroxide/color sensors after bleaching; vacuum transmitters and top/bottom temperature in the deodorizer; conductivity on wash waters; and solvent loss meters in extraction systems. With these in place, OEE typically improves by 5–10 points and off-spec rework is cut in half.

| KPI | Typical Value | Well-Optimized |

|---|---|---|

| Neutral oil yield | 97.0–98.0% of theoretical | 98.3–98.8% |

| Residual oil in meal (extraction) | 1.2–1.8% | 0.8–1.2% |

| Steam consumption (refining) | 180–240 kg/t oil | 150–190 kg/t oil |

| Electrical energy (pressing) | 35–55 kWh/t seed | 30–45 kWh/t seed |

| Phosphorus after degum | 10–30 ppm | <10 ppm |

| Tocopherol retention | 65–75% | 75–85% |

| Downtime (process-related) | 8–12% | 5–8% |

A 300 TPD rapeseed line upgraded to an integrated pre-press, extractor, and physical refining system with heat recovery and PLC-based parameter control. Within 90 days, results included: +0.6% neutral oil yield, −12% steam per ton refined, −18% filter aid consumption via phosphorus/soap control, and deodorizer FFA stabilized at <0.05%. The combined impact converted into higher throughput during peak season and more consistent brand color index.

Design with HACCP and ISO 22000 principles: allergen control (mustard family cross-contact), traceability from seed lot to finished oil, and validated cleaning-in-place for heat exchangers and deodorizer circuits. For export markets, align contaminants control with prevailing regulations and industry codes of practice, especially for polycyclic aromatic hydrocarbons, pesticide residues, and process contaminants. Documented critical limits (vacuum, temperature, phosphorus, and soap) are your best insurance against off-spec shipments.

From seed intake to deodorization, Penguin Group delivers one-stop, end-to-end rapeseed oil processing equipment—presses, extractors, centrifuges, bleaching systems, deodorization columns, and digital controls—engineered to lift yield and cut energy. Get a tailored line layout, capacity plan, and ROI model with implementation milestones.